The Industrial Walkie Reach Stacker from Hangcha is designed for versatility in the Industrial Walkie Stacker Series. It can act both as a counterbalanced stacker and a straddle stacker thanks to the scissor fork extension system. It acts as a counterbalanced stacker when its forks are extended. This allows it to handle non-standard pallets, enclosed pallets, and enclosed shelves easily. The reach stacker also acts as a straddle stacker when its forks are retracted allowing it to operate flexibly in narrow passages. This makes it perfect for warehouses, supermarkets, and workshops.

1. The A Series Electric Lithium-ion Industrial Walkie Reach Stacker has a smooth vivid profile and was designed to be ergonomic. The exterior of this forklift is powder coated in a durable, easy to see, green finish that designates it as a lithium-ion powered pallet truck.

2. This pallet truck uses stamped steel plates and injection molded parts. This creates a robust and durable product that is able to successfully take on the wear and tear of a warehouse environment.

1. All movements of the fork can be regulated with step-less speed. This provides more accurate and stable handling of goods.

2. The imported tiller’s function buttons are designed to allow the operator to comfortably operate the stacker.

3. The standard configuration creep speed driving function allows the truck to move at slow speeds. This increases the stacker’s maneuverability and allows it to stack goods even in confined spaces.

4. The stacker’s compact body and large rounded corner design make the truck perfect for narrow aisle operation.

5. The optional battery side roll out makes swapping out the battery fast and easy.

1. The Electric Power Steering (EPS) system makes maneuvering and load handling extremely easy.

2. The brushless AC travel motor features excellent acceleration, outstanding climbing ability, low heat emission, and is maintenance-free.

3. The latest CURTIS AC control system is highly efficient thanks to its accurate and stable control.

4. The CANBUS structure makes communication between all of the machine’s functions faster and more reliable.

5. The truck’s regenerative braking prevents it from sliding on a grade.

6. Tiller, switches, plug connectors, meters, and other components are all parts from industry known suppliers to ensure reliability, performance, and ease of service.

6. The forks and load backrest have a backward and forward tilt function as a part of the standard configuration. This creates a safer experience when loading and unloading goods.

1. The three-support-point, low center of gravity, and the high-strength steel plate structure feature a large residual load-bearing capacity and a long service life.

2. All wires and cables are protected to increase the reliability of the electrical system significantly.

3. The non-contact proximity switch features a long service life and is reliable.

4. The power plug is fastened to the stacker’s body. This prevents the plug from being damaged due to impact when the lithium-ion battery is lifted for installation.

1. Integrated Battery Management System (BMS) continually monitors energy management and ensures reliable operation.

2. HANGCHA provides these Lithium Iron Phosphate (LiFePO4 ) battery packs with up to a 5 year or 10,000 hour warranty.

3. See warranty certificate for specific warranty information on the Lithium Iron Phosphate battery packs.

1. As the truck’s steering angle increases, the truck’s speed decreases. This is a standard safety feature.

2. The reach stacker features three types of braking functions, release braking, reverse braking, and emergency braking, for safe operation.

3. The anti-sliding function on a grade ensures a safe operational workspace.

4. The emergency reversing button at top of the tiller protects the operator from being injured in case of an emergency during the backward operation of the truck.

5. The soft landing function reduces the mast’s lowering speed automatically when the forks are lowered to a height less than 3.9” from the ground. This is designed to protect the goods from hitting the ground too hard.

1. The brushless AC motor reduces operation costs significantly because it is maintenance-free.

2. The integrated battery indicator meter, timer, and fault self-diagnosis are convenient for maintenance.

3. The back cover can be opened fully to reveal all key components and parts. This is extremely convenient for the maintenance of the entire machine.

- AC Drive Motor

- CURTIS AC Drive Motor & Oil Pump Motor Controller

- Electric Power Steering System

- Automatic Deceleration at Turns

- Proportional Speed Regulation for all Fork Operations

- Multi-Function Battery Condition Meter

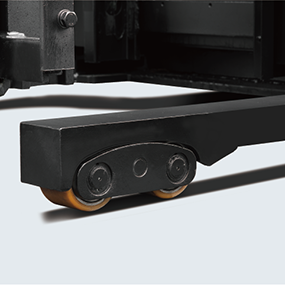

- High-Performance Load Wheels

- 42” Fork Length

- 7.9-33.5” Range for the Adjustable Outer Distance of Forks

- Forward and Backward Tilt of the Fork, by 3° and 5° Respectively

- Load Backrest

- 106.3“ Limited Free Lift 2 Stage Mast with Double Lifting Cylinders

- Soft Landing System

- Multi-Function Tiller

- Speed Limited when Fork is at Elevated Location

- Horn

- Key Switch

- Creep Speed Function

- Emergency Reversing Function

- 23.2” Forward Extension Distance of Fork

- Various Mast Heights

- Various Fork Lengths

- Side battery extraction

- Sideshifter

- Freezer

- Wire Mesh Mast Screen